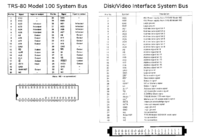

Disk/Video Interface: Cable

Special cable for Disk/Video Interface

For Model 100

Parts:

- 40pin DIP idc connector

- 40pin female idc connector, with polarity notch and strain-relief

- 40pin ribbon cable, 20 inches

Assembly:

- Crimp the cable in the DIP connector such that if you are looking at the dip connector with the #1 pin top-left and pins pointing away from you, the cable exits to the right, red stripe on top.

- For the DVI end of the cable...

- This assumes you ordered the actual DIP connector linked above, or have another one that connects it's pins to the conductors in the same pattern. Not all do. See note below.

- Grab the red wire and the one next to it as a single pair, and peel the pair away from the rest of the cable for about 2 to 3 inches. Repeat for the rest of wires, so the cable ends in 20 loose pairs.

- Take a sacrificial IDC connector, with strain relief clip, all snapped together but with no cable, so that the connector makes a thin open slot that's the perfect size for a cable to fit in. This will be used as a wire guide to hold all the loose pairs into their original flat ribbon cable shape so that you can crimp them all in a connector.

- Take the 1st pair of wires with the red wire, twist the pair 1/2 way, and insert it into the empty slot, right against one end of the slot, so that there is a grey wire at the edge of the slot, and the red wire is one position in from the end of the slot. Repeat the twist & insert for all the remaining pairs, until the whole cable is in the slot, but with every pair twisted.

- Crimp a new female IDC connector on the end of the cable. Make sure the triangle marker for pin-1 is on the red-stripe side of the cable. Wiggle the bundle of cables around a little to settle all those loose pairs into their proper positions before really crimping. It doesn't matter much which way the polarty notch points. There is room for the cable to fold back over the connector under the DVI if it needs to. What matters is that the pin-1 marker is on the same side of the cable as the red wire.

NOTES

- This pinout flatly violates the pinout written in the Service Manual for the DVI! Never the less, this is the way it actually needs to be wired.

- Most DIP IDC connectors connect pin 1 to conductor 2, and pin 40 to conductor 1. This is almost guaranteed to be the only iind you can get today. For instance:

- Various makes of DIP IDC connectors

- All of these connectors require twisting every 2 wires in the cable.

- But the original cable from Tandy had a special versiin of the connector where pin 1 connected to conductor 1 and pin 2 to conductor 40. That special connector doesn't need any twists in the ribbon cable.

- It's theoretically possible you might find that kind of connector, in which case you should not split and twist the wires.

- More sources for crimp-on dip40 plugs

For Model 102

Parts:

- 40pin boxed male idc connector, with polarity notch

- 40pin female idc connector, with polarity notch and strain-relief

- 40pin ribbon cable, 20 inches

Assembly:

- Crimp the male connector on one end of the cable. Make sure the red wire goes on the Pin-1 marker on the connector, and ideally put the polarity notch at the end of the cable.

- On the other end of the cable, same as for the DVI-end above for Model 100.

- (TODO: Make a new cable and update pics reflecting the following notes.)

- Note: These pictures show the wires twisted on the computer end instead of the DVI end. It actually doesn't make a difference where you put the twists, electrically. But it's better to put the twists on the DVI end for a few reasons. The twisted end of the cable is weaker, because the wires have been seperated from each other, making it more likely for individual pairs to have their connections weakened from pulling.

- Neater looking. The twists are hidden under the DVI.

- The DVI end suffers a less flexing than the computer end, because the computer moves around more than the DVI, and the computer end of the cable is handled more than the DVI end.

- The female connector on the DVI end has a strain relief clip.

- The socket in the DVI has latches that eject the connector out without having to pull on the cable.

For Model 200

Original/Official Cable

The actual original cable for Model 102 & 200 looked like this on the computer end. You can't get this thin close shroud on a crimp-on connector today, only on the pcb solder type.

Good Cable

One way to make a good cable for Model 200

Easy Cable

The Model 200 needs the same wiring as the 102, but the boxed male idc connector for the 102 above does not fit in the Model 200.

The simplest way to make a working cable for 200 is to use a cable with female IDC connectors on both ends (most ordinary IDE cables work), and then add a gender-changer male pin header to the computer end.

This is not ideal, because the resulting assembly is not polarity keyed, and the male pins are not protected from shorting or bending, and the pin header sometimes stays in the computer when you remove the cable instead of coming out with the cable, requiring you to pry it out with something.

But it's very simple to put together, especially if you use an ordinary IDE cable, you don't even have to crimp the connectors yourself. Just buy the pin header and stick it in any common pre-made IDE cable. And, this cable works on Model 102 exactly the same as Model 200.

More Pictures for Model 102/200 Easy Cable

Quick-n-Dirty neat trick

Another much easier way to get the wires crossed the right way (instead of that tedious and finnicky peeling & twisting 20 pairs), is just join 2 ordinary female idc connectors with a double ended male-male idc pin header. The arrangement of the connectors matters, and the rule is just match up the red stripe from both cables. For 102 & 200, you can dispense with one cable and use the 200 cable above. Thanks Mike Stein for this trick.